How to Choose the Perfect Connection Solution for Micromobility Battery Swap System

Micromobility is no longer a future trend, it is happening right now.

While resolving traffic congestion and providing the possibility of low-cost personal transportation with shared services, some of the most significant benefits of micromobility lie in its positive impacts on the environment.

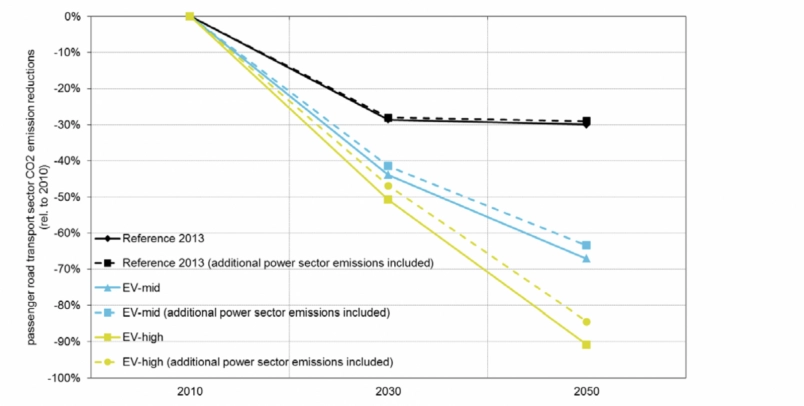

By replacing fuel-consuming vehicles with these electronically powered devices, greenhouse gas emissions could be cut significantly. A report from Ujet and Sustainability shows that replacing 8% of road vehicles with electric options can reduce carbon emissions by 80% by 2050.

To keep micromobility vehicles functioning smoothly and ensure the safety, efficiency, and stability of their swappable battery system is critical. In this article, we will discover 5 important factors that make a battery swap system's connection system successful.

Data sources:

Reduction in Size to Match Battery Design

Like all vehicles, the agility of micromobility devices is important so as is the size and weight of swappable batteries. To fit in the compactly designed battery packs, connectors should also be minimalized in size while matching the number of pins of customers’ requirements.

Guided Insertion

While in outdoor conditions, users may encounter difficulties when trying to charge their vehicles. A design that ensures the proper connection of the batter to the vehicle or the charging gun to the vehicle is essential. With the good design of the chamfer, the battery or charging gun could be inserted successfully and safely even up to 30° to 45° angle.

Charging Efficiency at Battery Swapping Stations

Charging efficiency is the priority, especially for shared micromobility vehicles. For fast charging to be realized, the connection system should be capable of transferring high currents while ensuring safety.

The Solution Should be Cost-Effective

Battery packs are massively produced items so the product should be cost-effective. As for the connector, a good choice of material and smart design that reduces the cost of tooling and production could significantly reduce the cost of the connection system.

Safety is Always First

Failure in battery safety and quality can result in electrical leakage, fire, or even body injury. The performance of battery packs and the charging process should be carefully monitored before launching to prevent incidents.

Nextron has been designing multiple micromobility battery connectors for the world’s major electric vehicle manufacturers. From e-bikes, e-scooters, and e-motorcycles to ev chargers, Nextron’s highly customizable products are trusted by clients worldwide.

Micromobility Battery Connector Products

| Product | Features | Applications |

|

|

E-bike, e-scooter |